Surface preparation is the essential first stage treatment of a steel substrate before the application of any coating, and is generally accepted as being the most important factor affecting the total success of a corrosion protection system.

The performance of a coating is significantly influenced by its ability to adhere properly to the substrate material. Residual mill scale on steel surfaces is an unsatisfactory base to apply modern, high performance protective coatings and is therefore removed by abrasive blast cleaning. Other surface contaminants on the rolled steel surface, such as oil and grease are also undesirable and must be removed before the blast cleaning process.

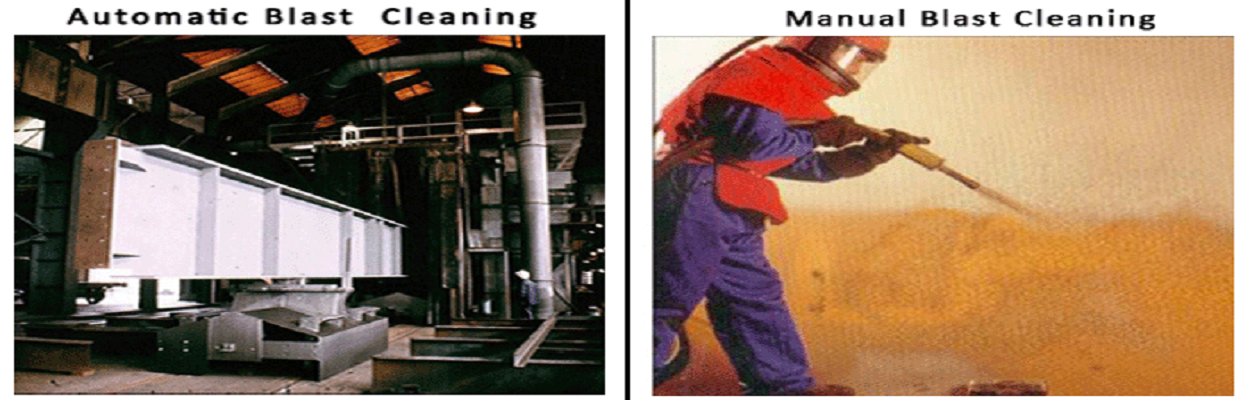

The surface preparation process not only cleans the steel, but also introduces a suitable profile to receive the protective coating. In most cases, we are able to get a clean surface by degreasing & pickling process for effective alloy formation during the Hot Dip Galvanizing process. However, in certain cases where the material is highly rusted and/or in painted condition (specially in case of pipes), we need to blast clean with Garnets / Steel Grit / Steel Shots.